MacGregor

Designed to perform with the sea. Smart inventory system proof of concept for MacGregor, a marine and offshore operator.

Holding workshops with a fellow designer and developer, planning with client’s representatives and designing the user interface.

Design work was done in collaboration with developers and client since POC was done in 4 weeks as a programmed, functional hybrid application.

How to keep cargo ship’s equipment and equipment stock levels on the same line? E.g. missing lashing equipment means lost time and costs to shipping company.

The process

Crew member’s task and safety aspect

In most cases the user would be a crew member doing surveys on vessel’s bays during the loading or unloading phase. The most consumable parts and equipment are under constant survey.

Improper stowage and securing of cargoes has resulted in numerous serious ship casualties and caused injury and loss of life, not only at sea but also during loading and discharge.

Lashing equipment

Turnbuckles pose problems as they take constant damage, come in dozens of various sizes, have color codings and embossed codes which doesn’t last long in harsh conditions.

So, how can damaged pieces be recognised and replaced efficiently?

Lost cargo caused by damaged or missing container securing cause millions of dollars financial loss to maritime industry each year.

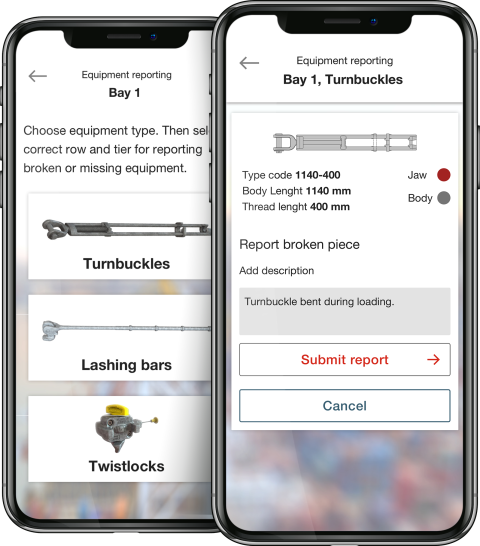

Recognising equipment

The vessel is divided into bays, rows and tiers. Each bay has a cargo securing manual presenting types of cargo securing equipment.

During the surveying task, a crew member selects the current bay. Next, the type of equipment which is missing or damaged. Finally, certain amount of parts per bay is presented with significant lengths for each part. Also color coding is shown if such still exists.

Submitting reports

After recognition of the correct part, a short description is demanded, describing what has supposedly happened before submitting the report.

Viewing reported and replaced equipment vessel’s officers are up to date of the vessel’s part stock situation.

Replacing parts

After reporting crew members can collect needed parts from vessel’s buffer stock and replace the damaged parts with correct parts. Bay’s status is visible during the replacement operation which can be monitored from the vessel’s bridge.

Surveying reports

Adding transparency to the survey-report chain, reports are also viewable to the shipping company’s management off-board.

When the vessel’s cargo securing equipment is running lower than suggested in the cargo securing manual, officers can take steps ordering substituting parts in advance.

Crew member start

Best example of how a team can achieve their best while working under tight deadline

Results & thoughts

For this project, there are lots of potential. Ideas how to scale it up and features which would bring more than extra value for maritime industry. There are also plans of a programme to bring green values to shipping business permanently.